HAVER CPA

Show more

Show fewer

The HAVER CPA measuring process is used for dynamic image analysis of grain sizes and grain shapes of dry and non-agglomerating particles of bulk materials. When fitted with the appropriate HAVER peripherals, this process can be used as a laboratory, technical centre or online version in different fields: gravel, sand, coke, coal, plastic granules, wood chippings, chemical and pharmaceutical products, fertilizers, foodstuffs and many more.

HAVER CPA 2-1 for particle sizes from 20 micron

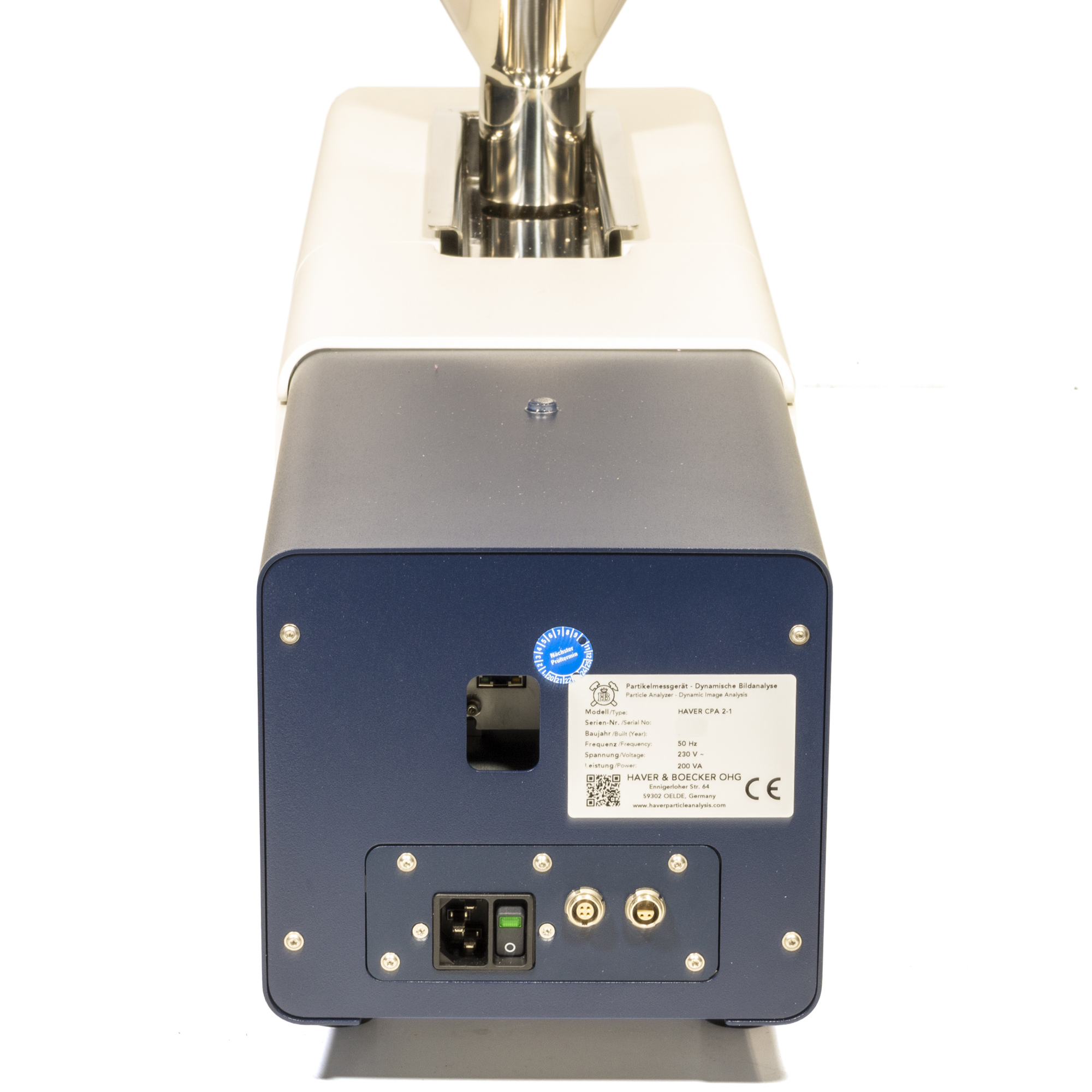

The HAVER CPA 2-1 is a laboratory unit for photo-optical size and shape analysisof dry and non-agglomerating particles of bulk material and therefore ideally suited for monitoring your product quality. It is a base model withbest cost-performance ratio. The HAVER CPA 2-1 can be operated using a computer or notebook with current Windows operating systems.haver cpaHAVER CPA measurement principle

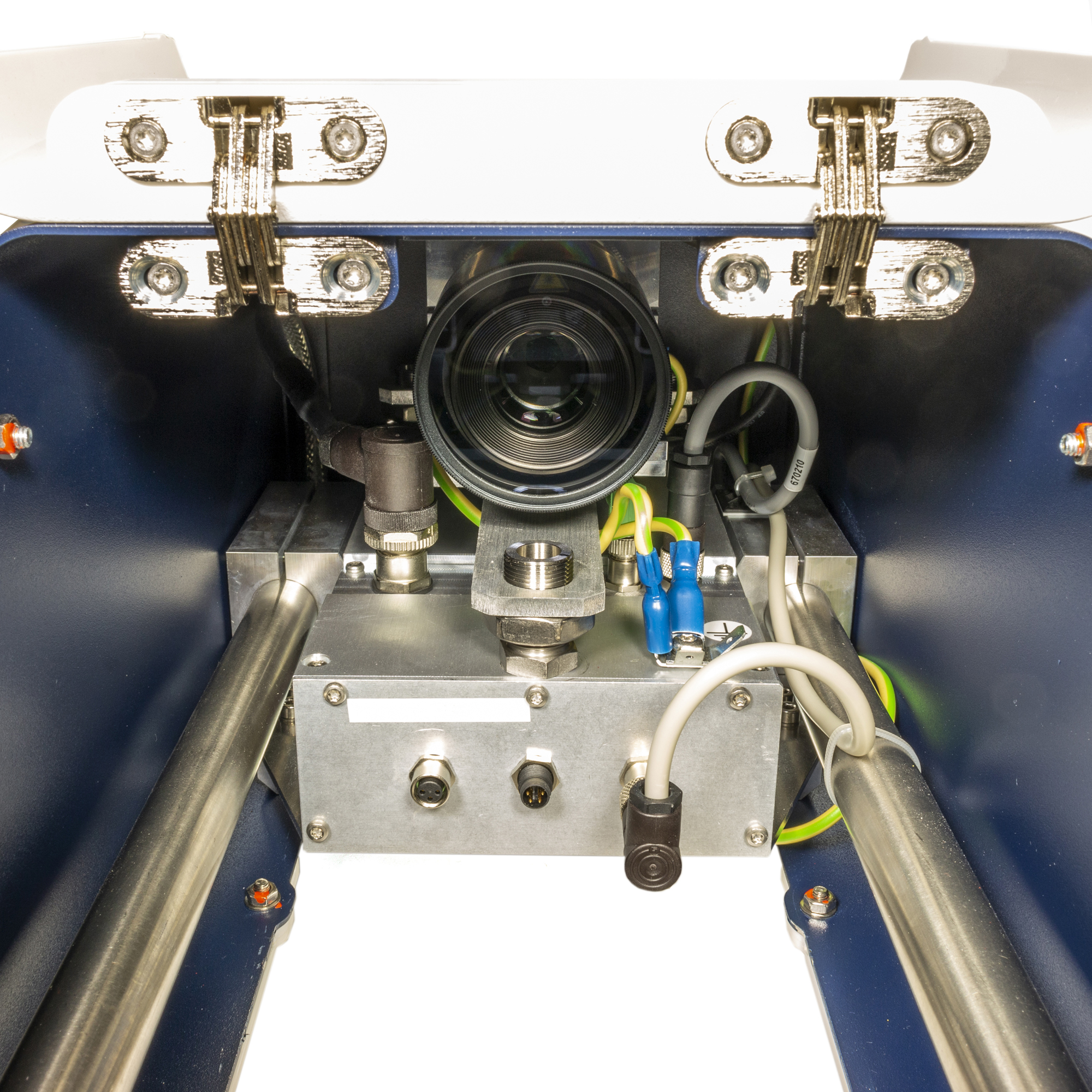

All HAVER CPA (Computerized Particle Analysis) measuring instruments utilize digital image processing technology for the dynamic image analysis of particles. The material sample is optimally dosed by a vibrating feeder whose amplitude is automatically regulated. In the measurement channel the particles fall between an LED light source and a digital line-scan camera and are scanned using the backlight technique as they free fall. The scanning range of the line scan camera is larger than the measurement channel width so that no partially scanned or completely undetected particles at the edges falsify the results.Unlimited images

The raw data coming from the camera do not form any single images with a certain frequency (fps), rather they generate an unlimited continuous image. Thus technology-related cut-off or double-measured particles are excluded. As opposed to other methods each particle is recorded, assigned an ID, and is saved with all measured values.HAVER REAL TIME

Because of the employed technologies and the direct communication between the CPA hardware and software, a real time evaluation is possible with HAVER REAL TIME. This does not only include a live video depiction and the real time size distribution, but also all shape distributions can be directly and simultaneously accounted for.Highest precision particle detection

The high-tech components and the high resolution used over the entire span of the measurement range allow the highest precision particle detection. This leads to the recording of all particles within the measurement range, and for them to be available in the highest quality and with all details. Also the smallest sample sizes can be measured and provide reproducible results.HAVER CpaServ

The HAVER CpaServ software is the artificial intelligence behind the CPA instruments and allow easy accessibility via the user surface. Using the software, single measurement operations can be defined and checked later by the software and to run automatically. All HAVER REAL TIME analysis data are processed in real time and are made available in a variety analyses and graphical depictions.Type

CPA 2-1

Mearuring range

0,020-30mm

Scaaning width

55mm

Voltage

230V

Horizontal resolution

2048 pixels

Pixel frequency

100 MHz

Dimensions (lxwxh)

800x200x355mm

Weight

ca. 16 Kg

Type

CPA 2-1

Mearuring range

0,020-30mm

Scaaning width

55mm

Voltage

230V

Horizontal resolution

2048 pixels

Pixel frequency

100 MHz

Dimensions (lxwxh)

800x200x355mm

Weight

ca. 16 Kg

| Article | Type | Mearuring range | Scaaning width | Voltage | Horizontal resolution | Pixel frequency | Dimensions (lxwxh) | Weight | Qty offer | |

| HAVE 205331725 | CPA 2-1 | 0,020-30mm | 55mm | 230V | 2048 pixels | 100 MHz | 800x200x355mm | ca. 16 Kg | ||

Type CPA 2-1 Mearuring range 0,020-30mm Scaaning width 55mm Voltage 230V Horizontal resolution 2048 pixels Pixel frequency 100 MHz Dimensions (lxwxh) 800x200x355mm Weight ca. 16 Kg | ||||||||||

Brochures

Videos

This video is disabled because of your cookie settings.

Brochures

Videos

This video is disabled because of your cookie settings.